API Flanges Manufacturers in India

API Flanges manufacturer, API Slip On Flange, API Welding Neck Flange, API Blind Flange, API Socket Weld Flanges, API Plate Flange, API Collar Flange, API Threaded Flange Manufacturers in India. ANSI/ASME B16.5, B16.47, B16.47, B16.36, B16.48 API Flanges

API Flanges manufacturer, API Flanges suppliers, Seamless/Seam Welded API Flanges, Fabricated API Flanges, API Flanges Suppliers in Indonesia, UAE, Saudi Arabia, Oman, Qatar, Australia.

Honesty Metal is specialized in manufacturing and supplying of API Flanges, Pipe Fitting, Forged Fittings, Butt weld fittings, Flanges since 1991, we manufacture wide range of API Flanges such as API Slip On Flange, API Welding Neck Flange, API Blind Flange, API Socket Weld Flanges, API Plate Flange, API Collar Flange, API Threaded Flange etc. as per International standard like ASME/ASTM/API, we are supplying & exporting API Flanges in seamless & welded both forms to more than 60 countries for over 2 decades, we have our dealers & distributors in Nigeria, Australia, Malaysia, Egypt, South Africa, Tanzania, Kenya, Mozambique, Angola, Gabon Germany, Turkey, France, United Kingdom, Italy, Netherlands, Iran, Iraq, Saudi Arabia, United Arab Emirates, Iisrael, Jordan, Oman, Kuwait, Qatar, Bahrain, Bangladesh, China, Indonesia, South Korea, Philippines, Singapore, Sri Lanka, Thailand, Vietnam, Brazil, Colombia, Argentina & United States of America, Honesty Metal is the only company in INDIA which is approved Manufacturer & supplier of API Flanges in 300 top companies worldwide. Few of them are ORPIC, NIORDC, Saudi Aramco, SABIC, PIDMCO, GASCO, KNPC, Indian Oil, BPCL, HPCL, NTPC, BARC & Indian Navy, Honesty Metal is ISO 9001:2008, ISO 14001, OHSAS 18001 Certified Company since 2006 & PED approved Manufacturer since 2008, Honesty Metal is India’s 6th largest Manufacturer, supplier & exporter of API Flanges .

Honesty Metal is manufacturing & exporting pipe flange from 1/2” thru 200”, 150 lbs to 3000 lbs including API Flanges, Carbon Steel flanges and Stainless Steel flanges according to ANSI, API, MSS, AWWA, DIN, JIS, BS and GB for the world market. We are experienced & specialized in manufacturing special ring flanges and other forgings as per drawing provided by our clients.

We supply ASME Code and Non Code Industrial flanges for the Petrochemical, Chemical & Waterworks industries. check our price before buying ANSI, API, AWWA pipe flanges in API Flanges, Carbon Steel flanges, Stainless Steel flanges and chrome steel flanges. Weld Neck flanges, flanges Slip on flanges, Blind flanges, Threaded flanges, socket weld flanges, Lap Joint flanges, Orifice Flanges in sizes 1/2″ to 198″.

Infrastructure :

We at Honesty Metal have 200 sets of equipment, including 20 sets of modern forging equipment, 140 high precision machine tools, floor-type lathes, drills, vertical lathes and other machining equipment, 2 electrical heating furnaces, 5 heat treatment furnaces, 2 PMI detection equipment, tensile machines, impact testers, hardness testers, metallographic analyzers, digital UT flaw detectors, etc. Forging process available in house: ring rolling forging, open die forging

API Flanges Datasheet

| API Flanges Datasheet | ||||||

| Max. Working Pressure | 2,000 PSI | 3,000 PSI | 5,000 PSI | 10,000 PSI | 15,000 PSI | 20,000 PSI |

| Test Pressure | 3,000 PSI | 4,500 PSI | 7,500 PSI | 15,000 PSI | 22,500 PSI | 30,000 PSI |

| Product Specification Levels | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

| API Temperature Rating | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) | K (-60 Deg C) |

| To | To | To | To | To | To | |

| Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | Y (+345 Deg C) | |

Integral, Blind, Target Blind & Test Flanges

| Min. Yield | 60,000 PSI | 60,000 PSI | 60,000 PSI | 60,000 PSI | 75,000 PSI | 75,000 PSI |

| Min. Tensile | 85,000 PSI | 85,000 PSI | 85,000 PSI | 85,000 PSI | 95,000 PSI | 95,000 PSI |

| Material | API 60K | API 60K | API 60K | API 60K | API 75K | API 75K |

Weld Neck Flanges

| Min. Yield | 45,000 PSI | 45,000 PSI | 45,000 PSI | 60,000 PSI | 75,000 PSI | 75,000 PSI |

| Min. Tensile | 70,000 PSI | 70,000 PSI | 70,000 PSI | 85,000 PSI | 95,000 PSI | 95,000 PSI |

| Material | API 45K | API 45K | API 45K | API 60K | API 75K | API 75K |

Weld Neck Flanges

| Min. Yield | 45,000 PSI | 45,000 PSI | 45,000 PSI | 60,000 PSI | 75,000 PSI | 75,000 PSI |

| Min. Tensile | 70,000 PSI | 70,000 PSI | 70,000 PSI | 85,000 PSI | 95,000 PSI | 95,000 PSI |

| Material | API 45K | API 45K | API 45K | API 60K | API 75K | API 75K |

Weld Neck Flanges

Dimensions 6B Flanges API 6A 5000 PSI Working Pressure

|

Flanges for Wellhead and Christmas Tree Equipment |

|||

| Max Working Pressure |

2000 PSI |

3000 PSI |

5000 PSI |

| Test Pressure | 3000 PSI | 4500 PSI | 7500 PSI |

| Product Spec Levels |

1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

| API Temp Rating |

K (-60 Deg C) to Y (+345 Deg C) |

K (-60 Deg C) to Y (+345 Deg C) |

K (-60 Deg C) to Y (+345 Deg C) |

|

Integral, Blind, Target Blind & Test Flanges |

|||

| Min. Yield | 60 000 PSI | 60 000 PSI | 60 000 PSI |

| Min. Tensile | 85 000 PSI | 85 000 PSI | 85 000 PSI |

| Material | API 60K | API 60K | API 60K |

|

Weld Neck Flanges |

|||

| Min. Yield | 45 000 PSI | 45 000 PSI | 45 000 PSI |

| Min. Tensile | 70 000 PSI | 70 000 PSI | 70 000 PSI |

| Material | API 45K | API 45K | API 45K |

|

Flanges for Wellhead and Christmas Tree Equipment |

|||

| Max Working Pressure |

10 000 PSI |

15 000 PSI |

20 000 PSI |

| Test Pressure | 15 000 PSI | 22 500 PSI | 30 000 PSI |

| Product Spec Levels |

1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

| API Temp Rating |

K (-60 Deg C) to Y (+345 Deg C) |

K (-60 Deg C) to Y (+345 Deg C) |

K (-60 Deg C) to Y (+345 Deg C) |

|

Integral, Blind, Target Blind & Test Flanges |

|||

| Min. Yield | 60 000 PSI | 75 000 PSI | 75 000 PSI |

| Min. Tensile | 85 000 PSI | 95 000 PSI | 95 000 PSI |

| Material | API 60K | API 75K | API 75K |

|

Weld Neck Flanges |

|||

| Min. Yield | 60 000 PSI | 75 000 PSI | 75 000 PSI |

| Min. Tensile | 85 000 PSI | 95 000 PSI | 95 000 PSI |

| Material | API 60K | API 75K | API 75K |

| 1. Nominal Size and Bore of Flange |

2. Max Bore | 3. Outside Dia Flange |

4. Tolerance (3) |

| 5. Max Chamfer | 6. Dia Raised Face |

7. Total Thk Flange |

8. Basic Thk Flange |

| 9. Dia Hub | 10. Dia Bolt Circle |

11. Number of Bolt Holes |

12. Dia of Bolts |

| 13. Dia Bolt Holes |

14. Bolt Hole Tolerance (Minimum -0.02) |

15. Length Stud Bolts |

16. Hub Length Threaded Line-Pipe Flange |

| 17. Hub Length Threaded Casing Flange |

18. Hub Length Welding Neck Line-Pipe Flange ±0.06 |

19. Neck Dia Welding Neck Line-Pipe Flange |

20. Tolerance (19) |

| 21. Max. Bore Weld Neck Flange |

22. Ring Number R or RX |

| 1 | 2 | 3 | 4 | 5 | 6 |

| 2.1/16 | 2.09 | 8.5 | ± 0.06 | 0.12 | 4.88 |

| 2.9/16 | 2.59 | 9.62 | ± 0.06 | 0.12 | 5.38 |

| 3.1/8 | 3.22 | 10.5 | ± 0.06 | 0.12 | 6.62 |

| 4.1/16 | 4.28 | 12.25 | ± 0.06 | 0.12 | 7.62 |

| 5.1/8 | 5.16 | 14.75 | ± 0.06 | 0.12 | 9 |

| 7.1/16 | 7.16 | 15.5 | ± 0.12 | 0.25 | 9.75 |

| 9 | 9.03 | 19 | ± 0.12 | 0.25 | 12.5 |

| 11 | 11.03 | 23 | ± 0.12 | 0.25 | 14.63 |

| 1 | 7 | 8 | 9 | 10 | 11 |

| 2.1/16 | 1.81 | 1.5 | 4.12 | 6.5 | 8 |

| 2.9/16 | 1.94 | 1.62 | 4.88 | 7.5 | 8 |

| 3.1/8 | 2.19 | 1.88 | 5.25 | 8 | 8 |

| 4.1/16 | 2.44 | 2.12 | 6.38 | 9.5 | 8 |

| 5.1/8 | 3.19 | 2.88 | 7.75 | 11.5 | 8 |

| 7.1/16 | 3.62 | 3.25 | 9 | 12.5 | 12 |

| 9 | 4.06 | 3.62 | 11.5 | 15.5 | 12 |

| 11 | 4.69 | 4.25 | 14.5 | 19 | 12 |

| 1 | 12 | 13 | 14 | 15 | 16 |

| 2.1/16 | 7/8 | 1 | +0.06 | 6 | 2.56 |

| 2.9/16 | 1 | 1.12 | +0.06 | 6.5 | 2.81 |

| 3.1/8 | 1.1/8 | 1.25 | +0.06 | 7.25 | 3.19 |

| 4.1/16 | 1¼ | 1.38 | +0.06 | 8 | 3.88 |

| 5.1/8 | 1½ | 1.62 | +0.06 | 10 | 4.44 |

| 7.1/16 | 1.3/8 | 1.5 | +0.06 | 10.75 | 5.06 |

| 9 | 1.5/8 | 1.75 | +0.09 | 12 | 6.06 |

| 11 | 1.7/8 | 2 | +0.09 | 13.75 | 6.69 |

| 1 | 17 | 18 | 19 | 20 | 21 | 22 |

| 2.1/16 | … | 4.31 | 2.38 | +0.09 -0.03 |

1.72 | 24 |

| 2.9/16 | … | 4.44 | 2.88 | +0.09 -0.03 |

2.16 | 27 |

| 3.1/8 | … | 4.94 | 3.5 | +0.09 -0.03 |

2.65 | 35 |

| 4.1/16 | 3.88 | 5.19 | 4.5 | +0.09 -0.03 |

3.47 | 39 |

| 5.1/8 | 4.44 | 6.44 | 5.56 | +0.09 -0.08 |

4.34 | 44 |

| 7.1/16 | 5.06 | 7.13 | 6.63 | +0.16 -0.03 |

5.22 | 46 |

| 9 | 6.06 | 8.81 | 8.63 | +0.16 -0.03 |

6.84 | 50 |

| 11 | 6.69 | 10.44 | 10.75 | +0.16 -0.03 |

8.53 | 54 |

Surplus stock at Honesty Metal

- Pipe Fittings

- Butt Weld Fittings

- Forged Fittings

- Socket Weld Fittings

- Threaded Fittings

- Flange

ANSI/ASME steel flanges

|

|

EN/PED steel flanges

|

|

BS steel flanges

|

|

JIS steel flanges

|

|

Valve Components

|

|

Plain washer, gasket

|

|

Flange Standard

|

|

Types of API Flanges

|

|

Our Specialization in Below API Flanges

|

|

|

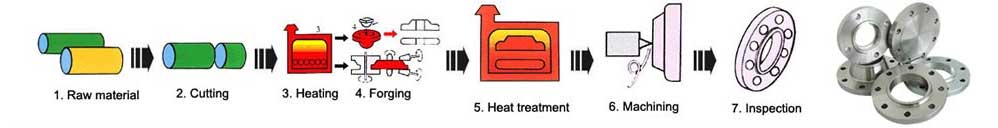

Steel Flanges Manufacturing Process

API Flanges Project Reference List

| PROJECT NAME / CUSTOMER | Honesty Metal | GRADES | LOCATION | YEAR |

|---|---|---|---|---|

| GAS DEVELOPMENT PROJECT | API Flanges/ PIPE FITTINGS, BRANCH OUTLETS | INCOLOY 825 | INDONESIA | 2015 |

| INDORAMA | API Flanges/ PIPE FITTINGS AND BRANCH OUTLETS BW – SW – THRD | A105 – A350 LF2 – A106B- A333 GR6 – A234 WPB – A420 WPL6 – A182 F304L | THE NETHERLANDS | 2015 |

| GAS AND CONDENSATE EXPORT SYSTEM | API Flanges/ PIPE FITTINGS AND BRANCH OUTLETS BW – SW | A182 F316L – A182F44 A182 F44 , A312S31254, A182 F316L, A105.N, A105 HDG, A350 LF2, A106 Gr.B, A106 Gr.B HDG , A333 Gr.6, A234 WPB |

KUWAIT | 2015 |

| QUALITY STAMP TRADING -SAUDI ARAMCO | API Flanges/ PIPE FITTINGS , BRANCH OUTLETS SW | A105, A105 GALV, A350 LF2, A182F304L, A182F316L, A403 WP316L, A182F321, A182F44, A182F5, CU90/10 UNS C70610 |

SAUDI ARABIA | 2014-2015 |

| REFINERY OFF GAS PROJECT | API Flanges/ PIPE FITTINGS, BRANCH OUTLETS BW-THRD, NIP OUTLETS | A105, A105 HDG A350 LF2, A182 F304/ 304L, A182F316/316L, A182F11, A105N, A106B, A234WPB, A333 |

BELGIUM | 2014-2015 |

| MA’ADEN WA’AD AL SHAMAL PHOSPHATE | BUTT WELD / FORGED FITTINGS AND BRANCH OUTLETS SW-BW | A350LF2, F304L, F316L, F904L, A182F60, ALLOY20 A105N, A106B, A234WPB, |

SAUDI ARABIA | 2014-2015 |

| NORTH WEST REDWATER | API Flanges/ PIPE FITTINGS SW & NPT | A350LF2,A420WPL6, A182F304L-F316L,WP304L,HAST,C276 |

CANADA | 2014-2015 |

| CANADA NWR PROJECT | API Flanges/ PIPE FITTINGS , BRANCH OUTLETS SW & NPT | F304L/316L/317L/347H/321H F11/F22/ UNS08825 |

CANADA | 2014-2015 |

| DENIZ 2 PROJECT | BUTT WELD / FORGED FITTINGS SW & NPT | A 105, A105 GALVA, A350LF2, A333 Gr6, A234WPB-A420WPL6, F304L, WP304L |

AZERBAIJAN | 2014 |

| ADMA OPCO ABU DHABI | BUTT WELD / FORGED FITTINGS, BRANCH OUTLETS BW-THRD, LATERAL, OUTLETS | A694 F52, A182F321, A182F316, A105.N, A312TP316L, A312 TP321, A182 F53 SUPER DUPLEX |

UAE | 2014 |

| SAUDI ARAMCO HOLLAND | API Flanges/ PIPE FITTINGS | CuNi 9010 | SAUDI ARABIA | 2014 |

| MISSAN OIL Comp.PETROCHINA IRAQ | API COUPLINGS | L80 | IRAQ | 2014 |

| SAUDI ARAMCO | API Flanges/ PIPE FITTINGS, BRANCH OUTLETS BW-SW-THRD | API 400, A182 F5, A182F316L, A182F304L, A105 |

SAUDI ARABIA | 2014 |

| OIL AND GAS INC | API Flanges/ PIPE FITTINGS AND BRANCH OUTLETS BW | UNS NO 6625 | BRAZIL | 2014 |

| SHIDDIRGANG PROJECT | API Flanges/ PIPE FITTINGS, BRANCH OUTLETS BW-SW-THRD | BANGLADESH | 2014 | |

| SAUDI ARABIAN MINING COMPANY | API Flanges/ PIPE FITTINGS AND BRANCH OUTLETS SW – BW | A105, A105 GALV, A350LF2A182F304L, A182F316L |

SAUDI ARABIA | 2014 |

| GRUPO CUNADO | FORGED STEEL FITTINGS | A105,A182F304L, A182F316L,F321, | TURKEY | 2013-2014 |

| ALSTOM | FORGED STEEL FITTINGS AND BRANCH OUTLETS | A105, A182F304L, A182F316L | MOROCCO, SOUTH AFRICA | 2010 |

| GAS TURBINE POWER PLANT PROJECT | API Flanges/ PIPE FITTINGS AND BRANCH OUTLETS SW | A105, A182F316L | IRAQ | 2014 |